TM-120 Taxanaha Kartoonka Daawada Tooska ah

Sharaxaad Gaaban:

Mashiinka wax lagu shubo kartoonada ee dawadan inta badan waxa ay ka kooban tahay todoba qaybood: habka dawada in-quudinta, qayb silsilad farmashiyaha in-quudin, habka nuugid kartoonnada, habka riixaya, habka kaydinta kartoonnada, makaanamka qaabaynta kartoon iyo makaanim wax soo saarka.

Waxay ku habboon tahay alaabooyinka sida kaniiniyada dawooyinka, balaastarka, waji-xidhka, cuntooyinka, iyo qaababka la midka ah, iwm.

Faahfaahinta Alaabta

Tags Product

Faahfaahinta Alaabta

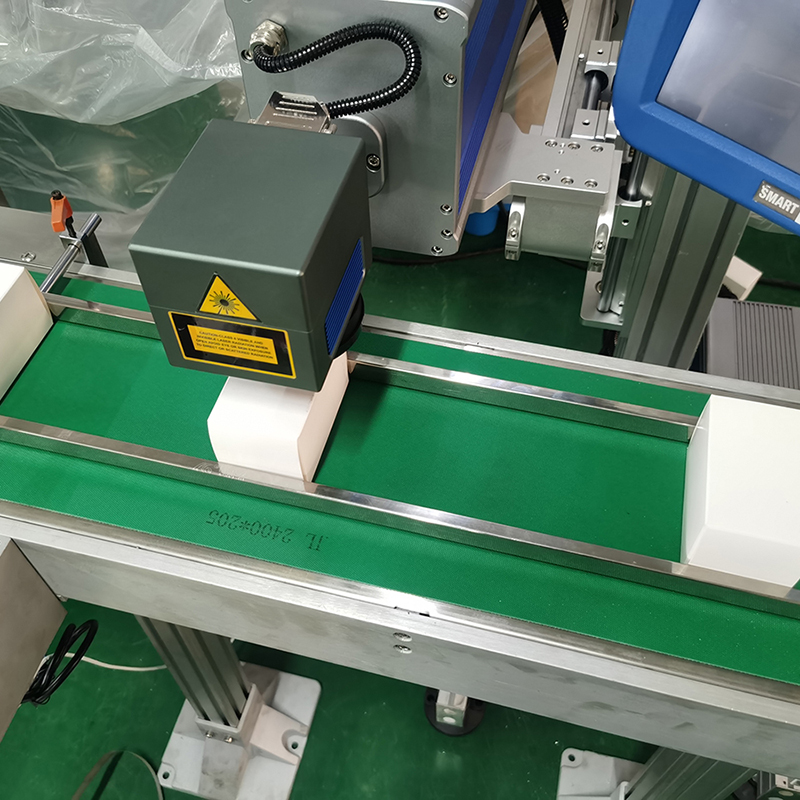

Kartoonkani waxa uu si toos ah u tiriyaa oo u quudinayaa kaniiniyada ama alaabta la midka ah iyo kartoonada, nuuga oo laalaa buug-gacmeedka, furo kartoonada, ku riixo alaabta gudaha kartoonnada, daabaca koodka, xira kartoonnada iyo wareejinta alaabta dhammaatay. Waxaa jira laba nooc oo shaabadeynta kartoonada: nooca tucker iyo nooca koollada, oo ay dooran karaan baahida dhabta ah ee macaamiisha.

Qaybta quudinta waxaa loo habeyn karaa iyadoo loo eegayo baahiyaha dhabta ah.

Mashiinkan waxaa loo isticmaali karaa si madaxbannaan ama khadka wax soo saarka, iyadoo lala xiriirinayo mashiinnada kor iyo hoosba.

Astaamaha

Xakamaynta 1.PLC oo leh HMI, fududahay in la shaqeeyo iyo dayactirka.

Hawl-wadeenadu waxay hubin karaan heerka wax-soo-saarka, waxay dejiyaan cabbirrada iyadoo loo eegayo baahiyaha wax-soo-saarka dhabta ah. Marka uu jiro qaylo-dhaan khaldan, sababta khaldan waxa lagu tusi karaa HMI si ay si sahlan u baarto.

2.Xawaaraha ugu weyn ee mootada waxaa xakameynaya VFD. VFD waxay maamushaa codeeyaha xagasha korodhka ah, kaas oo u dhaqma halkii uu ka ahaan lahaa habka kamarada dhaqameed, oo aad uga sii saxsan meelaynta.

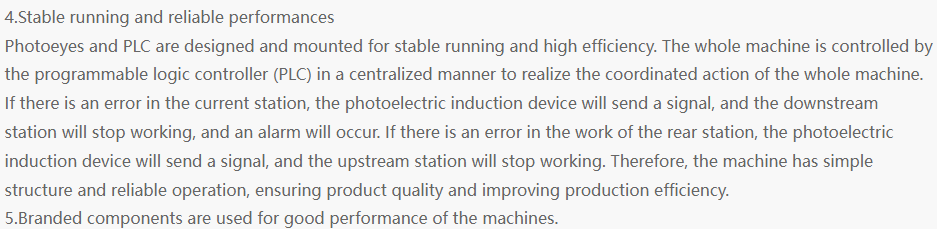

3.Mashiinkaani wuxuu ku qalabeysan yahay shaqeynta digniinta.

Haddii qalliinku khaldan yahay, si toos ah ayuu u joogsan doonaa. Marka mishiinku u shaqeeyo in ka badan ama ka hooseeyo qiimihii la dejiyay, si toos ah ayuu u qaylo dhaamin doonaa. Waxay ku qalabaysan tahay E-stops. Marka badhamada E-stop la riixo, dhammaan hawlaha xakamaynta pneumatic iyo korantada waa la daminayaa. Intaa waxaa dheer, ilaalinta qulqulka xad-dhaafka ah ayaa loogu talagalay qaybta gelinta korantada si loo joojiyo mishiinka isla markiiba marka ay la kulanto culeyska inta lagu jiro hawlgalka. Waxaa intaa dheer, mashiinka wax lagu duubo waxaa lagu qalabeeyaa dabool badbaadada plexiglass si ay uga ilaaliso hawlwadeenada dhaawacyada suurtagalka ah.

Tilmaamaha Farsamada

| Xawaaraha | 30-120 kartoon/daqiiqo (waxay kuxirantahay cabbirada kartoonada) | |

| Kartoon | Tilmaamid | 250-350g/㎡ (wuxuu u baahan yahay hubinta cabbirrada kartoonnada) |

| Cabbirka (L×W×H) | (70-200)mm × (30-80)mm × (15-60)mm | |

| Buugga | Tilmaamid | 60-70g/㎡ |

| Cabbirka aan la tirtirin (L×W) | (80-250)㎜× (90-180)㎜ | |

| Laalaabyada (L×W) | 1 ~ 4 laab | |

| Hawo cufan | Cadaadiska hawada | ≥0.6mpa |

| Isticmaalka Hawada | 120-160L/daqiiqo | |

| Korontada | 380V 50HZ (waa la beddeli karaa) | |

| Matoorka ugu muhiimsan | 1.5kw | |

| Cabbirka (L×W×H) | 3400㎜×1200㎜×1750㎜ | |

| Miisaanka | Qiyaastii 1200kg | |

Hordhaca Qaybta

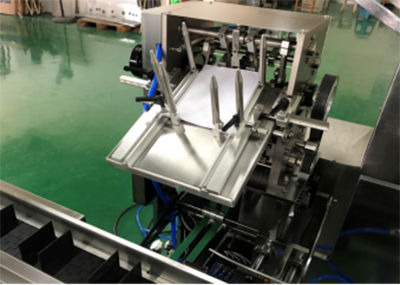

Kaydinta kartoonada (Ilaa 400pcs oo kartoon ah)

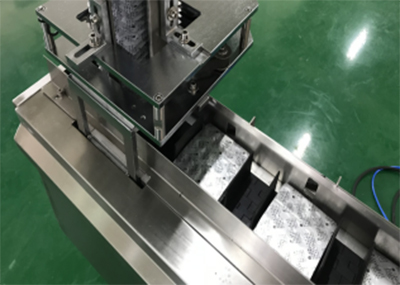

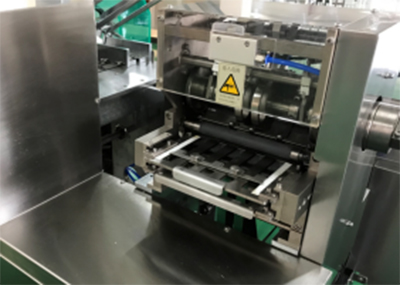

Kiniiniyada Pusher Mechanism

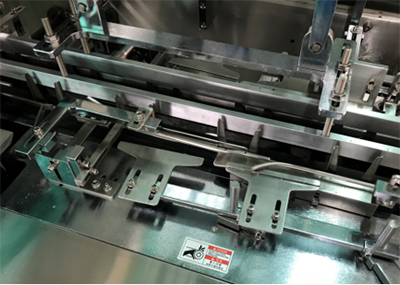

Silsiladda Gudbinta Kartoonka

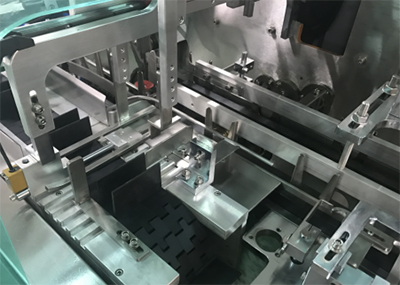

Qaabaynta Kartoonka iyo Mechamismka Tucker

Habka saarista sanduuqyada madhan

Silsiladda haanta la hagaajin karo ee Quudinta kiniinka

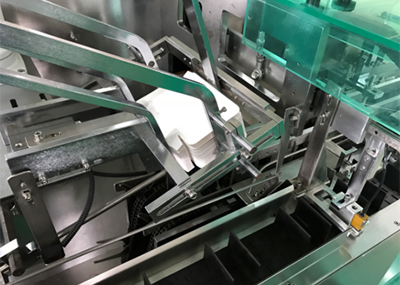

Farsamaynta Gacan-ku-laabashada iyo Quudinta

Kiniinnada Tooska ah ee Quudinta iyo Farsamaynta Tirinta